Vehicle NVH Testing - Noise, Vibration, and Harshness

Noise, vibration, and harshness (NVH), also known as noise and vibration, is the study and modification of the noise and vibration characteristics of vehicles, particularly cars and trucks. Our complete NVH testing and NVH analysis solutions are ideal for optimizing noise and vibration of the vehicles, such as reduction, design, and quality assurance of the interior and exterior noise.

What is NVH?

To enhance vehicle performance, comfort, and brand recognition, we offer a wide range of flexible and flexible solutions for capturing and analyzing NVH data in the field of noise, vibration, and harshness (NVH), all compliant with international standards and supported by calibration services.

What is noise?

To enhance vehicle performance, comfort, and brand recognition, we offer a wide range of flexible and flexible solutions for capturing and analyzing NVH data in the field of noise, vibration, and harshness (NVH), all compliant with international standards and supported by calibration services.

What is vibration?

Vibration is an oscillation that causes noise and disturbance. Vibration is generally of concern due to the physical effects which can cause disturbance to people, disruption in electrical systems, and failure or breakdown in mechanical systems. Shakers and controllers are techniques used to test vibration issues.

What is harshness?

Harshness is generally used to describe the severity and discomfort associated with both vibration and noise. It is a qualitative system based on desired characteristics rather than on quantifiable measurements.

NVH testing

NVH testing is widely used in the automotive industry for the reduction, design, and quality assurance of interior and exterior vehicle noise or vibration. The process usually takes place during the vehicle development of passenger cars.

NVH can be tonal such as engine noise, or broadband, such as road noise or wind noise. Basically, it is everything that drivers or passengers can either hear and feel from a car while driving, such as wind noise, road noise, bumps from the suspension, or vibrations from the engine.

NVH applications

Our one-stop acoustic test solutions and vibration test solution cover all essential sound and vibration measurement applications such as:

- Sound Level Meter

- Sound Power

- Sound Quality

- Sound Intensity

- Octave Band Analysis

- Reverberation Time RT60

- Pass-by Noise

- Brake Noise and Squeal

- FFT Analysis

- Order Tracking

- Rotational and Torsional Vibration

- Whole Human Body Vibration analysis

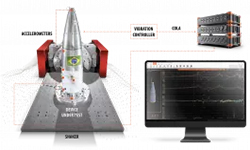

Noise, vibration, and harshness (NVH) testing involve subjecting a full vehicle, component or subassembly to vibrations at different frequencies, as a means of determining mode shapes and isolating buzzes, squeaks, and rattles. Typical instrumentation used to measure NVH include microphones, accelerometers and force gauges, or load cells. Component and subassembly NVH tests are most commonly performed using a vibration shaker while entire vehicles usually on the test track or road simulator testbeds.

Many NVH facilities will have semi-anechoic chambers and rolling road dynamometers. Typically, signals are recorded by a DAQ system directly to a hard disk via sensors and an ADC converter (analog-to-digital converter), and a suitable signal conditioner.

Improving NVH can be achieved by reducing the source strength, by interrupting the noise or vibration path, or by absorption of the noise or vibration energy. Techniques used to help identify NVH include part substitution, modal analysis, rig squeak and rattle tests (complete vehicle or component/system tests), lead cladding, acoustic intensity, transfer path analysis, and partial coherence.

WELLTEK helps develop, design, or troubleshoot NVH issues:

- Sound packaging: dash/floor silencer, headliner, door trims, etc.

- Pass-by noise test

- Powertrain NVH: engine and transmission NVH testing

- Whole-body vibration

- Aeroacoustics

- Interior noise: squeak and rattle, road noise

- Sound design and sound quality

- Component noise: component induced NVH

- Brake noise and Brake squeal

- Tire acoustics: tire and road sound

- Intake and exhaust noise

- Sound pressure level: stationary road vehicles

- Source Path Contribution - SPC

- Powertrain Structural Optimization - Finite Element Calculation

- Combustion Noise

-

Brake Noise Testing - According to VDA 303 Guideline

WELLTEK Brake Noise testing solution, also known as Brake Squeal, is ideal for detecting and tracking noise caused by mechanical vibration in various braking systems based on the VDA 303 guideline algorithm.

-

Class 1 Sound Level Meter - Sound and Noise Measurement

WELLTEK class 1 sound level meter is the golden standard for sound and noise measurement reinvented with the WELLTEK approach.

-

Octave Band Analysis and Analyzer

Octave band analysis is an indispensable tool for sound measurement because it gives a close approximation of how the human ear responds. WELLTEK octave band analyzer meets all of the IEC and ANSI specifications for octave filters.

-

Sound Intensity Measurement

A perfect tool for sound intensity level measurement and noise source determination brought to an entirely new level by WELLTEK. The solution brings a simple and intuitive measurement process while offering the utmost precision and industry unmatched adaptability.

-

Sound Power Measurement Solution

WELLTEK sound power measurement solution merges the best of both worlds: widely established sound power measurements with familiar, distinctive user interface and industry unmatched adaptability. Rate and compare different noise sources with ease and exactness while simultaneously monitor any number of additional parameters.

-

Sound Quality Measurement and Analysis

A sound quality measurement is an indispensable tool for successful sound engineering. It addresses the need to empirically evaluate how sound produced by different kinds of machines are perceived by the human ear.

-

Reverberation Time RT60 Measurement

When room acoustics properties are at issue, the RT60 reverberation time solution represents an essential tool for obtaining an accurate measurement of reflected sound. The easy setup enables reliable measurement for effective modification of room parameters and easy achievement of desired reverberation time.

-

FFT Spectrum Analyzer - Vibration and Frequency Analysis

The WELLTEK FFT spectrum analyzer has it all: top performance, real-time FFT analysis, advanced cursor and marker functions, high freely selectable line resolution, flexible averaging, and advanced functions for in-depth frequency analysis.

-

Order Analysis - for Rotating Machinery

Order analysis is a technique for analyzing noise and vibration signals in rotating or reciprocating machinery that runs at a steady or varying speed. It can provide complete diagnostics of generators, combustion engines, compressors, turbines, pumps, and rotating shafts.

.jpg)

.jpg)

.jpg)